CNC (computer numerical control) computers are crucial in the automotive industry. These sophisticated devices are computer-controlled and offer excellent levels of performance, precision, and quality that would be difficult to accomplish with a manual operation.

CNC machining has made operations that have been previously unlikely feasible. Several different kinds of CNC machines are used to do the same, just how other sections that CNC machining can make. Each CNC machine is unique in terms of its construction, operation, and product capabilities.

Continue reading to learn about the various kinds of CNC machines and their distinct functions:

CNC Milling Machine

A CNC mill is one of the most popular types of CNC machining. It uses computer commands to cut different materials. Mills can convert complex programs of letters and numbers to drive the spindle in a variety of ways.

Many mills employ G-code, which, as previously said, is a structured programming language understood by the majority of CNC machines. A CNC mill can perform various tasks, including shoulder milling, face milling, drilling, tapping, and spinning. The majority of CNC mills have three to six axes.

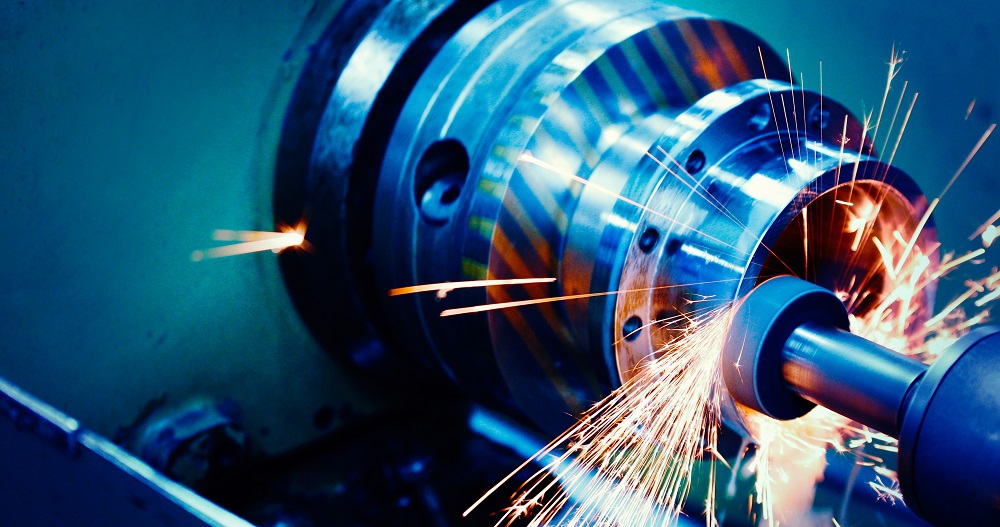

CNC Lathe

A CNC lathe is a machine that cuts product pieces while they are rotating. CNC lathes are capable of making accurate cuts quickly by using a variety of materials.

As opposed to manual lathes, a CNC lathe machine is mighty in terms of precision. It frequently uses fewer axes than CNC milling machines, ultimately making the overall machinery smaller and lightweight.

CNC lathe machines have controls similar to CNC mills and can translate G-code and other specialized programming languages. Mori Seiki, HAAS, and Okuma are among the most well-known CNC lathe manufacturers. Also, CNC lathes have a close similarity to manual lathe machines.

CNC Router

A CNC router is somewhat similar to the traditional handheld router machine used to cut different materials. This kind of CNC machine helps with wood, steel, aluminum, composites, rubber, and foam cutting.

A CNC router machine closely resembles a CNC mill machine. It includes using programmable logic control to route workpieces that enable the system to operate. CNC routers minimize pollution and improve efficiency by delivering various products in a fraction of the time that most devices do.

Final Words

As it is evident, there are numerous types of CNC devices, each of which serves a unique purpose. To hire a professional CNC machinist, operator, or programmer, you must know how these CNC machines function. And, then only you should move on to rent a CNC machine (เช่า CNC, which is the term in Thai).